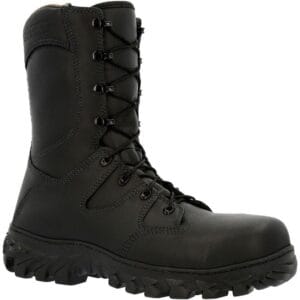

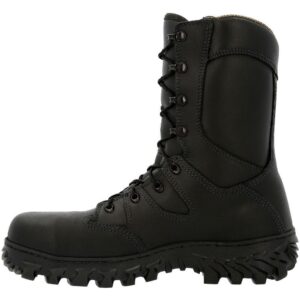

Rocky Code Red Structure NFPA Rated Composite Toe Fire Boot

$390.00

Rocky Fire Boots

Rocky fire boots are built for fearless firefighters. Crafted with premium flame-resistant leather, these boots offer unmatched durability, waterproof protection, and steel-toe safety. Designed with slip-resistant soles and cushioned insoles, they ensure stability and comfort in high-heat, high-stakes environments. Trust Rocky fire boots for performance under pressure.

Rocky Fire Boots: Your Complete Guide to Rugged Protective Footwear

When it comes to reliable fire service footwear that can withstand the most demanding conditions, Rocky fire boots have built a formidable reputation among firefighters nationwide. These American-made firefighter boots combine decades of footwear manufacturing expertise with specific innovations designed for the unique challenges of emergency response. Whether you’re battling wilderness blazes as a hotshot or responding to structural fires in an urban environment, understanding what makes Rocky fire boots stand out can help you make an informed decision about this crucial piece of protective equipment.

In this comprehensive guide, we’ll explore everything you need to know about Rocky fire boots—from their specialized wildland models to structural firefighting options and everything in between. You’ll discover why these fire fighter boots have earned the trust of firefighters across the country and how to select the right model for your specific operational needs.

About the Author: Our team includes wildland firefighters and structural fire professionals who have personally tested Rocky fire boots in real-world conditions. We’ve worked with multiple models across various terrains and emergency scenarios to provide firsthand, trustworthy insights into their performance and durability.

The Rocky Legacy: American-Made Quality

A Heritage of Durability

Rocky Brands, Inc. has been manufacturing footwear in Nelsonville, Ohio since 1932, bringing nearly a century of craftsmanship to their fire boots line. What sets Rocky fire boots apart is their commitment to American manufacturing and their understanding of the specific demands faced by emergency responders. This heritage translates into firefighter boots that are built to last, with attention to detail that comes from generations of footwear expertise.

Why Firefighters Choose Rocky

The popularity of Rocky fire boots among fire professionals isn’t accidental. These fireman boots consistently deliver where it matters most:

-

Proven durability in punishing conditions

-

Excellent comfort for long shifts and extended operations

-

Reliable safety features that meet or exceed standards

-

American manufacturing supporting domestic jobs

-

Competitive pricing for exceptional quality

Rocky Fire Boot Models: Finding Your Perfect Match

Wildland Fire Boots

Rocky’s rocky wildland fire boots are specifically engineered for forest and brush fire operations:

Rocky Code Red Hotshot Logger Fire Boot:

-

8-inch height for ankle support in rough terrain

-

Vibram® logger outsole for superior traction

-

Heat-resistant materials for protection from ground heat

-

Waterproof construction with breathable membranes

-

NFPA 1977 compliant for wildland firefighting

Rocky Mid-Height Wildland Boots:

-

6-inch design for lighter weight and mobility

-

Flexible construction for varied terrain

-

Enhanced breathability for hot conditions

-

Quick-drying materials for wet environments

Structural Firefighting Boots

For traditional structural fire response, Rocky offers leather structural firefighting boots:

Rocky Structural Fire Boots:

-

NFPA 1971 compliant for structural firefighting

-

Full-grain leather construction for durability

-

Steel toe and shank for impact and puncture protection

-

Waterproof and chemical-resistant materials

-

Heat-resistant outsoles that won’t melt

Technical and Duty Boots

Rocky’s lineup also includes options for technical rescue and daily duty:

Technical Rescue Models:

-

Electrical hazard protection

-

Enhanced flexibility for confined spaces

-

Multi-hazard resistance

-

Comfort-focused designs for extended wear

Key Features of Rocky Fire Boots

Advanced Safety Technology

Rocky fire boots incorporate multiple protective systems:

Impact and Compression Protection:

-

Steel or composite safety toes meeting ANSI standards

-

Puncture-resistant plates in the midsoles

-

Reinforced ankle support for stability on uneven ground

-

Metatarsal guards in select models

Thermal and Environmental Protection:

-

Heat-resistant outsoles that withstand extreme temperatures

-

Flame-resistant materials throughout construction

-

Waterproof membranes that keep feet dry

-

Insulated options for cold weather operations

Comfort and Performance Engineering

Where Rocky fire boots truly excel is in their wearability:

Cushioning and Support Systems:

-

Shock-absorbing midsoles that reduce foot fatigue

-

Anatomic footbeds that support natural foot positioning

-

Padded collars and tongues for comfort around the ankle

-

Arch support systems for all-day comfort

Climate Management Features:

-

Moisture-wicking linings that keep feet dry

-

Breathable construction for temperature regulation

-

Ventilation systems in select wildland models

-

Quick-drying materials for wet conditions

The Rocky Code Red Hotshot Logger: A Closer Look

Why It’s a Hotshot Favorite

The Rocky Code Red Hotshot Logger fire boot has become legendary among wildland firefighters for good reason:

Logger-Style Design Benefits:

-

Heeled outsole provides superior traction on inclines

-

High-cut design offers excellent ankle support

-

Aggressive lug pattern grips various terrains

-

Sturdy construction withstands rough treatment

Hotshot-Proven Features:

-

Lightweight for its class reduces fatigue during long shifts

-

Excellent break-in characteristics compared to competitors

-

Durable materials that last through multiple seasons

-

Reliable waterproofing that holds up in wet conditions

Real-World Performance

Feedback from hotshots using the Rocky Code Red Hotshot Logger consistently highlights:

-

Superior comfort during 16+ hour shifts

-

Excellent durability even with daily rugged use

-

Outstanding traction on slippery or steep terrain

-

Good value for the quality and performance

Selecting the Right Rocky Fire Boots

Assessing Your Operational Needs

Choosing the perfect Rocky fire boots involves careful consideration of several factors:

Primary Response Environment:

-

Wildland operations require NFPA 1977 compliance

-

Structural firefighting demands NFPA 1971 certified boots

-

Technical rescue needs specialized protection features

-

EMS and daily duty benefit from all-day comfort designs

Terrain and Climate Considerations:

-

Mountainous terrain needs aggressive tread patterns

-

Flatland operations may prioritize lightweight designs

-

Wet environments require reliable waterproofing

-

Hot climates benefit from enhanced breathability

The Complete Sizing Guide

Getting the right fit is crucial with Rocky fire boots:

Proper Measurement Approach:

-

Measure both feet at the end of the day

-

Wear the socks you’ll use on duty

-

Consider any orthotics you regularly use

-

Account for normal foot swelling during long shifts

Fit Assessment Checklist:

-

Adequate toe room (about thumbnail’s width)

-

Secure heel fit without slippage

-

No pressure points or tight areas

-

Comfort through full range of motion

-

Proper arch support alignment

-

Use our boot fitting guide] for detailed measurement instructions.

Rocky Boots and NFPA Compliance

Understanding Safety Standards

Rocky fire boots are engineered to meet rigorous safety requirements:

NFPA 1977 (Wildland Firefighting):

-

Heat and flame resistance testing

-

Cut resistance requirements

-

Slip resistance standards

-

Electrical hazard protection

-

Overall durability and performance testing

NFPA 1971 (Structural Firefighting):

-

Compression and impact protection

-

Puncture resistance standards

-

Extended heat resistance requirements

-

Whole boot flexibility testing

-

Water penetration resistance

-

Review current [NFPA safety standards] for complete compliance details.

Comparing Rocky to Other Fire Boot Brands

How Rocky Stands Out

Understanding the Rocky fire boots advantage in the competitive fire service market:

| Feature | Rocky Fire Boots | Other Major Brands |

|---|---|---|

| Manufacturing | American-made in Ohio | Often overseas production |

| Price Point | Competitive for quality | Varies widely by brand |

| Wildland Focus | Excellent hotshot-specific models | Mixed wildland offerings |

| Comfort Technology | Advanced cushioning systems | Varies by brand and model |

Maintenance and Care for Rocky Fire Boots

Routine Maintenance Protocol

Proper care extends your Rocky fire boots’ service life significantly:

After Each Use:

-

Remove insoles and allow to air dry separately

-

Brush off surface debris, mud, and soot

-

Rinse with clean water if exposed to chemicals or saltwater

-

Stuff with newspaper to absorb moisture and maintain shape

Weekly Maintenance:

-

Deep clean with manufacturer-recommended products

-

Condition leather components as needed

-

Inspect for damage, excessive wear, or separation

-

Check sole integrity and lug wear patterns

Specialized Care by Model

Different Rocky fire boots require specific maintenance approaches:

Leather Boot Care:

-

Use quality leather cleaners and conditioners

-

Avoid petroleum-based products that can degrade stitching

-

Allow natural drying away from direct heat sources

-

Regular conditioning to maintain water resistance

Synthetic Material Maintenance:

-

Mild soap and water cleaning

-

Avoid harsh chemicals that can damage materials

-

Regular inspection of seams and bonds

-

Hardware function checks

The Break-in Process: What to Expect

Realistic Break-in Timeline

New Rocky fire boots require a proper break-in period:

Typical Timeframes:

-

Wildland boots: 1-3 weeks of regular wear

-

Structural boots: 2-4 weeks due to heavier construction

-

Gradual improvement in comfort and flexibility

-

Progressive molding to your specific foot shape

Effective Break-in Strategies:

-

Wear during light duties initially

-

Use your regular duty socks during break-in

-

Flex and bend the boots during wear sessions

-

Address specific pressure points with appropriate techniques

Cost Analysis and Investment Value

Understanding the Price Range

Rocky fire boots represent a significant investment in your safety:

Typical Price Ranges:

-

Wildland models: $250-$400

-

Structural fire boots: $300-$500

-

Technical rescue options: $200-$350

-

Premium custom builds: $400-$600

Long-term Value Considerations

The investment in Rocky fire boots pays off through:

-

Extended service life with proper maintenance

-

Reduced foot fatigue during long operations

-

Potential department reimbursement programs

-

Excellent durability that reduces replacement frequency

Real-World User Experiences

Firefighter Testimonials

What actual users say about their Rocky fire boots:

Wildland Firefighter Feedback:

-

“My Code Red Hotshots lasted two full seasons on a hotshot crew”

-

“The break-in was surprisingly comfortable compared to other brands”

-

“Traction on steep inclines has been exceptional”

-

“Waterproofing held up through multiple wet deployments”

Structural Firefighter Reports:

-

“Daily comfort in station boots is outstanding”

-

“Structural models provide excellent protection without excessive weight”

-

“Durability has exceeded my expectations”

-

“The American manufacturing quality is noticeable”

Frequently Asked Questions (FAQ)

Q1: How do Rocky fire boots fit compared to other brands?

Most users find Rocky fire boots run true to size, but many experienced firefighters recommend ordering a half-size larger than your regular street shoes to accommodate swelling during long shifts and thicker socks. The Rocky Code Red Hotshot Logger specifically tends to have a roomier toe box than some competitors, which many hotshots appreciate during extended wear.

Q2: Are Rocky wildland fire boots waterproof?

Yes, most rocky wildland fire boots feature waterproof construction with breathable membranes like Gore-Tex® or similar technologies. However, waterproofing can compromise over time with heavy use, and proper maintenance is essential to maintain water resistance. Regular conditioning of leather components and seam inspection helps preserve waterproof capabilities.

Q3: How long do Rocky fire boots typically last with regular use?

With proper care and maintenance, Rocky fire boots typically last 2-4 seasons for wildland firefighters and 3-5 years for structural firefighters, depending on call volume and operating conditions. Many users report their Rocky boots outlasting competing brands, particularly in the wildland firefighting environment where durability is constantly tested.

Q4: Can Rocky fire boots be re-soled when the outsoles wear out?

Many Rocky fire boots models can be factory re-soled, extending their service life significantly. This is particularly true for the logger-style wildland boots. However, resoling feasibility depends on the condition of the uppers and the specific model. Contact Rocky customer service or an authorized repair center to determine if your specific boots are candidates for resoling.

Q5: Do Rocky fire boots meet all necessary NFPA standards?

Yes, Rocky fire boots are manufactured to meet applicable NFPA standards, with wildland models compliant with NFPA 1977 and structural models meeting NFPA 1971 requirements. Always verify the specific certification for the model you’re considering and check for the NFPA label inside the boot to ensure current compliance for your specific fire service application.

Reviews

There are no reviews yet.